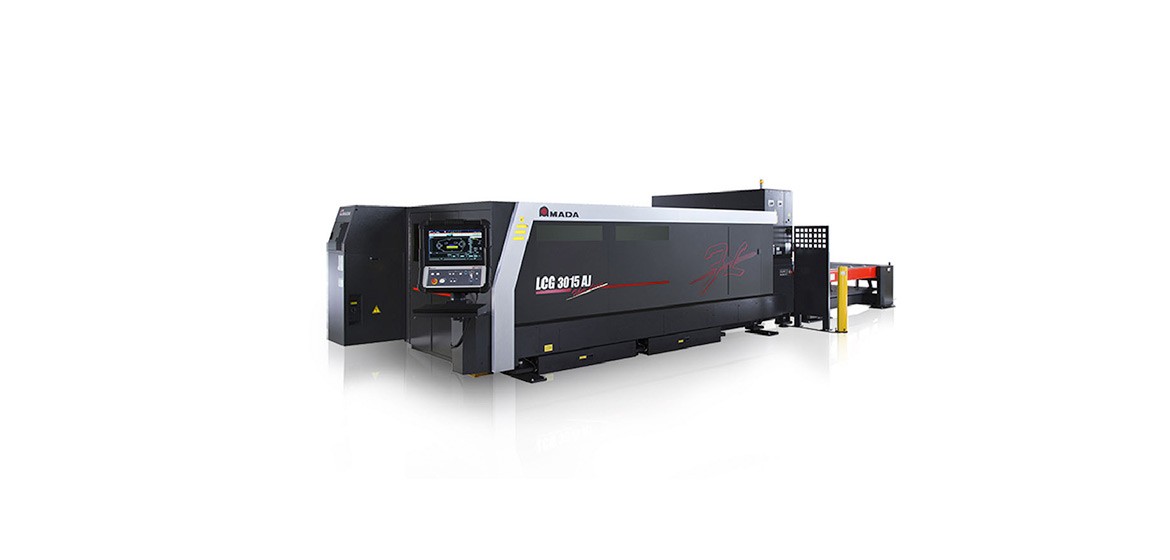

Redhill has recently invested in a new Amada LCG3015-AJ flatbed laser cutting machine, equipped with an Amada developed fibre engine. With high cutting speeds and low running costs, and the ability to cut copper, brass and titanium, the machine sets a new benchmark for precision performance, ensuring optimum productivity and value.

For Redhill, this provides key benefits in terms of speed and efficiency. With up to 38% higher processing speeds and fastest in class feed rates, processing time is greatly reduced, while laser precision cutting ensures new levels of accuracy, enabling Redhill to offer customers faster service and exceptional quality. In addition, the fibre laser is environmentally friendly and the Amada LCG3015-AJ uses a combination of compressed air and Nitrogen assist gasses, while reduced steel loads allied with precision cutting ensure wastage is kept to a minimum.

Committed to an on-going expansion programme, Redhill continues to invest in new products, plant and equipment, ensuring an unrivalled metal manufacturing capability and maintaining its position as one of the UK’s leading manufacturers of access, storage and manual handling equipment providing consistently high standards of quality, safety and reliability.