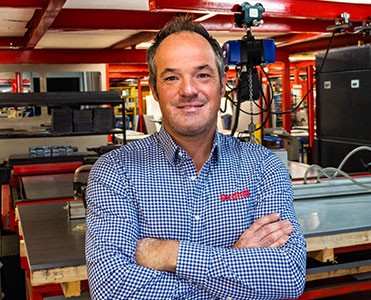

Managing Director

A manufacturing capability, passion and expertise that spans 45 years.

Our extensive portfolio of British-made access, handling and storage equipment includes over 3,000 standard products, all designed, manufactured and assembled at our purpose-built factory in Redditch.

Drawing on a manufacturing capability that spans over 45 years, our team is made up of skilled experts who are passionate about their craft and take genuine pride in their work. Blending this craftsmanship with innovations in technology such as our state-of-the-art laser cutter, robotic arm, powder coating facility and CAD, we design, create and construct products at the forefront of safety, quality and durability standards.

Directors

-

Andy Colley

andy@redhillmanufacturing.co.uk

Office: +44 (0)1527 529002Andy Colley became Managing Director in 2019, moving up from Operations Director and taking over the role from his father, Ken Colley. As a grandson of the original founder, Eric Barnard, Andy represents a new generation of the family and initially started at Redhill in 2003, working in each area of the business to gain all-round experience.

Influential in moving the business forward, Andy has continually researched new technologies and manufacturing methods, and was instrumental in installing a new laser cutting machine in 2016, bringing significant quality improvements to Redhill’s processes and products.

Achieving the BSI Kitemark for Redhill’s range of Mobile Safety Steps in 2014 was a particular highlight for Andy, achieved after rigorous testing and revisions, and highlighting the company’s commitment to quality, safety and durability.

As the new Managing Director, Andy is focused on identifying efficiencies to help Redhill continually improve. This involves overseeing a new IT system, expanding the team and embracing new technologies to improve speed and accuracy, refine products, develop prototypes and build stock levels.

Core focus for the moment is building distributor relationships across the UK and globally, but mindful of the company’s long, local heritage, Andy is especially proud Redhill continues to be a family-run business, with a friendly, open and supportive culture. Testament to that is a loyal and dedicated workforce, many of whom have been with Redhill for over 35 years!

-

Sam Colley

sam@redhillmanufacturing.co.uk

Office: +44 (0)1527 386347Director & HR

Sam Colley

Sales

-

Ross Anderson

ross@redhillmanufacturing.co.uk

Office: +44 (0)1527 386347

Mobile: +44 (0)7572 064444Sales Director

Ross Anderson

-

Sophie Bates

sophie@redhillmanufacturing.co.uk

Office: +44 (0)1527 529002Customer Account Manager

Sophie Bates

-

Carly Laydon

carly@redhillmanufacturing.co.uk

Office: +44 (0)1527 529002Customer Service Representative

Carly Laydon

Production

-

Kevin Balcombe

kevin@redhillmanufacturing.co.uk

Office: +44 (0)1527 529002As one of Redhill’s longest serving members of staff, Kevin Balcombe knows the business inside out. After joining as a 17-year old apprentice in 1983, he spent two years on the shop floor, paint spraying, assembling, driving a fork lift truck and generally seeing how the company operated.

In 1989, he was appointed Works Manager which involves running the shop floor, updating drawings as the product range increases and resourcing the workplace with new machinery and ideas. Over the years, this has seen Kevin help with expanding the premises, bringing Redditek back in-house, introducing new Health & Safety standards, setting up a British Standard quality system, and overseeing machinery, security and fire systems.

A key change in 1992 involved the delivery of a new CNC tube-bending machine, the first of its kind in the UK, which could be programmed via computer, eventually leading to the computerisation of all functions. In 2016, Kevin oversaw the introduction of a laser cutting machine in 2016, transforming manufacturing capability; and in 2019, the addition of the Solid Works 3D CAD package, revolutionising drawing capability.

With 40 years’ experience, it’s no surprise to learn Kevin is generally one step ahead of everybody else when it comes to manufacturing knowledge. Kevin says he treats the company as if it were his own, which means leading by example, learning from mistakes and making time to laugh, at least once a day!

Operations Director

Kevin Balcombe

-

Robert Underhill

rob@redhillmanufacturing.co.uk

Office: +44 (0)1527 529002Production Manager

Robert Underhill

-

Holly Jones

holly@redhillmanufacturing.co.uk

Office: +44 (0)1527 529002Production & Accounts

Holly Jones

-

Scott joined Redhill Manufacturing in 2003. In his current role he is responsible for leading the team who focus on the production of larger steps in the Redhill Steptek range.

Leader: Large Step Manufacture

Scott Williams

-

Trevor joined Redhill Manufacturing in 1988. In his current role he is responsible for overlooking the finishing of all products and leading the associated team.

Leader: Product Finishing

Trevor Cains

Redhill are the sole manufacturers of British Standard BS EN 131-7 steps

Our range of British Standard Mobile Safety Steps has been awarded the internationally recognised BSI Kitemark Standard for quality. Manufactured at Redhill’s Midlands base in the UK, each product within the range complies fully with the new British Standard BS EN 131-7.

Well Built In Britain

Spanning over six decades and three family generations the Redhill story is one that we are extremely proud of.

Our History

Key processes and capabilities

Committed to exceptionally high standards

-

Redhill’s BS Mobile Safety Steps were the first of their kind to be awarded the British Kitemark.

-

Our own exacting standard ensure our products are built to the highest levels of reliability, safety and durability.

Engineering Apprenticeships: Excellent Employer

Redhill are proud to run a successful apprenticeship scheme investing in young talent. We work closely with Next Gen Makers to ensure apprentices have the right training and support to achieve their professional goals in engineering.

Charities we support

-

Little Hearts Matter

The only charity in the UK dedicated to supporting and empowering anyone affected by the diagnosis of a single ventricle heart condition – or half a working heart.

-

MacMillan Cancer Support

Providing services for people living with cancer at every stage of their cancer experience. Macmillan provide emotional, practical, physical, and financial support.

-

The Fire Fighters Charity

The Fire Fighters Charity offers specialist, lifelong support for members of the UK fire services community, empowering individuals to live happier and healthier lives.