I would like to address all of my Royal Redhill Stakeholder subjects and congratulate them on a great 2023!

I have taken a retrospective look at all the great things that have happened this year, with exception to the best moment being my arrival, obviously:

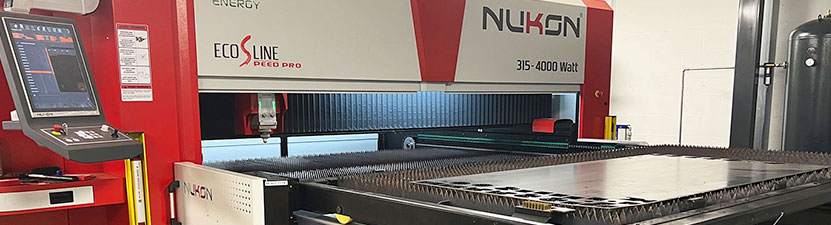

January: Sheet Fibre Laser Installed and Running

Redhill’s premises were equipped with cutting-edge technology, including the recently acquired Nukon ECO 315 4kw sheet fibre laser. With our expert team fully trained, this addition elevates our manufacturing capability, allowing us to handle intricate cuts and shapes for a range of products in-house, significantly enhancing efficiency and reducing lead times.

February: Rob Joins the Team

We welcomed Production Manager Rob Underhill and expanded our CAD facility, which has helped us massively increase production in 2023.

March: Redhill Visit Troy Means Business Event

The team visited the highly regarded TMB2023 event at the Silverstone Circuit. As first time exhibitors, we gained a lot from the experience, finding Troy members to be a welcoming, friendly group of people and learning about new products on the market that we wouldn’t otherwise have known about.

April: MD and Sales Director Take on 72 holes of Golf In One Day

Redhill’s MD, Andy Colley and Sales Director Ross Anderson took part in Macmillan Cancer Support 2023 Longest Golf Day Challenge. A gruelling 72 holes of golf were completed, we wont mention the score!

May: New Premises Enters Final Phase of Development

The final phase involved the final fitting of Unit 14 having new windows, asbestos removal, and knocking through floors to provide welding areas, jigs and addition storage space. Unit 15 became our new office space, and Queen Quinn’s area for working and sleeping. Mainly sleeping.

June: Redhill Bake Sale for Fire Fighters Charity

The Bake Sale was organised at our premises, selling a selection of amazing cakes and cookies to staff and visitors, raising vital funds for the charity. In total, £536.82 was raised as Directors Andy and Sam matched the amount raised in sales.

July: Kitemarked Steptek Quality Red Range modified to further improve safety

The BSI inspectors recommended that we increase the dimensions of the base framework on our BSI Steptek range, to ensure it provided an even greater level of stability. It wasn’t a precursor to our steps continuing to hold the BSI Kitemark, it was just a suggestion, but it was one we were happy to take on board. Steptek mobile safety steps was the first and is still the only range of mobile safety steps to be awarded the BSI Kitemark.

August: Our New Long Nose Tube Benders Arrive

Our highly anticipated investment finished it’s testing period and was brought to the door in early August. These British Made machines further our commitment to create a state-of-the-art factory with the latest in manufacturing technology.

September: Tube Lasers Arrive from Turkey

After a long journey from Turkey to Redhill HQ, the brand new machines were slowly moved into position.

October: Tube Laser Up and Running!

The machine is an incredibly adaptable laser cutting system designed to deliver precise results. It can effortlessly process tubes and pipes with a diameter of up to 180mm, as well as profiles and sections measuring up to 125mm x 125mm.

November: Team Get Their Advent Calendars Ready for December

Employees at Redhill Manufacturing areable to count down the days to Christmas with the sweet surprise behind each calendar door (and a bauble full of dog treats for my hard work).

We would like to thank everyone for their ongoing support. As you can see, we have had an exciting 12 months with positive changes across the entire business including new machinery, staff, changes to the facility, and myself 🐶

We have high hopes for 2024 with even more investment in infrastructure including a brand new powder coating plant reminiscent of our setup in the old factory.

To see our opening times over the festive period, please click here.

Have an excellent Christmas and New Year, we hope Santa Paws brings you everything on your list!

Queen Quinn and the Team at Redhill Manufacturing.